What isPosMAC?

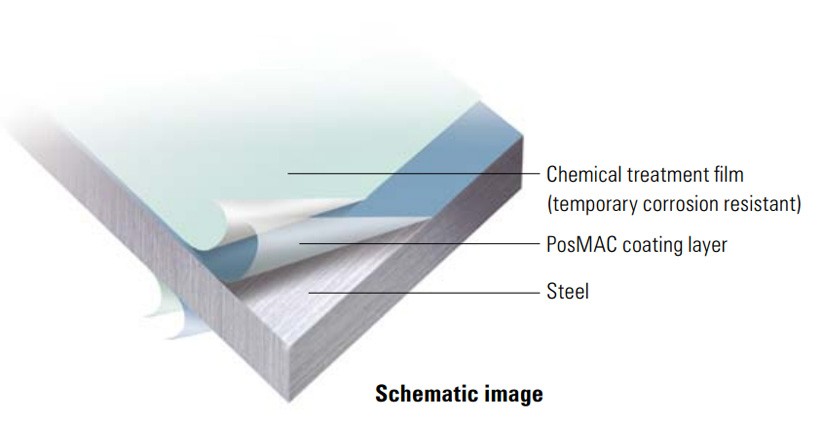

PosMAC(POSCO Magnesium Aluminium alloy Coating product) is a ternary alloy coated steel(Zn- 3%Mg- 2.5%Al) with high corrosion resistance developed with POSCO’s own technology. * PosMAC®is the registered trademark of POSCO.

PPosMAC is a corrosion resistant products that is 5 to 10 times stronger resistance than that of a normal hot-dip galvanized steel sheet(GI, GI(H)) with the same coating weight. PosMAC has an excellent cross-section corrosion resistance; normal thick plating products can be replaced with this product.

The same processing, assembly and painting process can be applied to PosMAC as one would apply to GI.

PosMAC is superior to GI in corrosion resistance on flat, machined, cross-section parts and is superior to galvalume in cross-section corrosion resistance.

| Quality items | PosMAC3.0 | GI | Galvalume | |

|---|---|---|---|---|

| Hardness(Hv) of coating layer | 110 ~ 130 | 60 ~ 80 | 80 ~ 100 | |

| Friction characteristics | ◎ | X | △ | |

| Corrosion resistance | Flat sheet | ◎ | X | ◎ |

| Bending | ◎ | △ | △ | |

| Cup | ◎ | △ | ◎ | |

| Cross-section | ◎ | △ | X | |

| Chemical resistance | ◎ | △ | △ | |

| Weldability | ◎ | ◎ | ◎ | |

| Classification | Pohang #1CGL | 광양 #2CGL | |

|---|---|---|---|

| Operation date | 2012. 04 | 1992. 06 | |

| Capacity | 750 thousands ton/yea | 510천톤/년 | |

| Product dimensions | Thickness | 0.4~4.5mm | 0.45~2.3mm |

| Width | 800~1,650mm | 720~1,860mm | |

| Coating weight | 60~400 g/m2 | 80~350 g/m2 | |

| Product grade | General, Structura | 자동차용, 일반용, 구조용 | |

| Post treatment | Chromate(Cr6+, Cr3+), Cr-free, Oilin | Chromate(Cr3+), 도유 | |

-

Entry

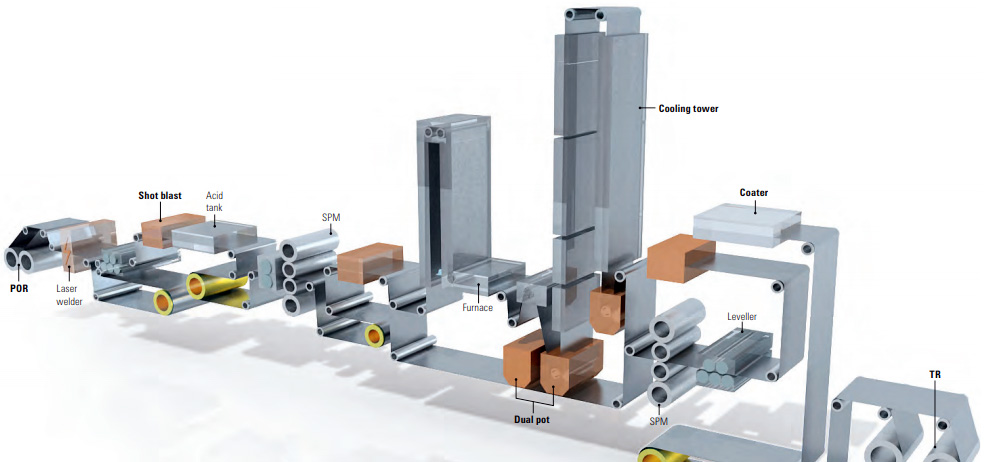

The equipments at the entry section are composed of two pay off reels and a welder.

-

Shot blast, Pickling

The scales from an HR coil can be removed completely by passing through the shot blast and pickling tank.

-

Galvanizing

Zn-Mg-Al is coated onto the surface of the steel sheet after passing the annealing furnace in the pot reserved for PosMAC, and then the targeted coating weight is achieved by spraying high pressurized air from the air knife.

-

SPM & Post treatment

In order to obtain the flat shape and elegant surface, PosMAC product get passed through a skin pass mill. Also to prevent any white rust, product surface is coated with Cr-free or chromate to improve corrosion resistance property.

-

Inspection & Coiling

The equipment at the exit section are composed of an inspection table and an oiler equipment where the products are inspected synthetically and judged whether they are adequate for sale.

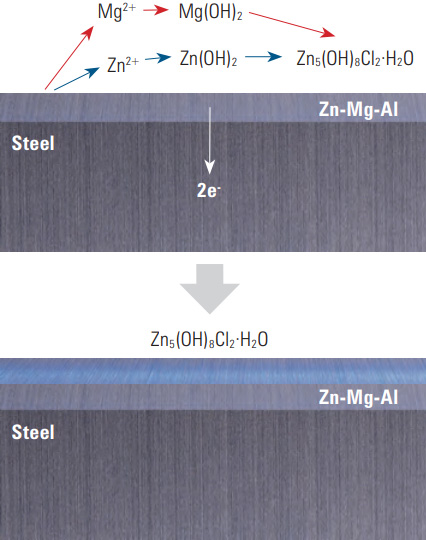

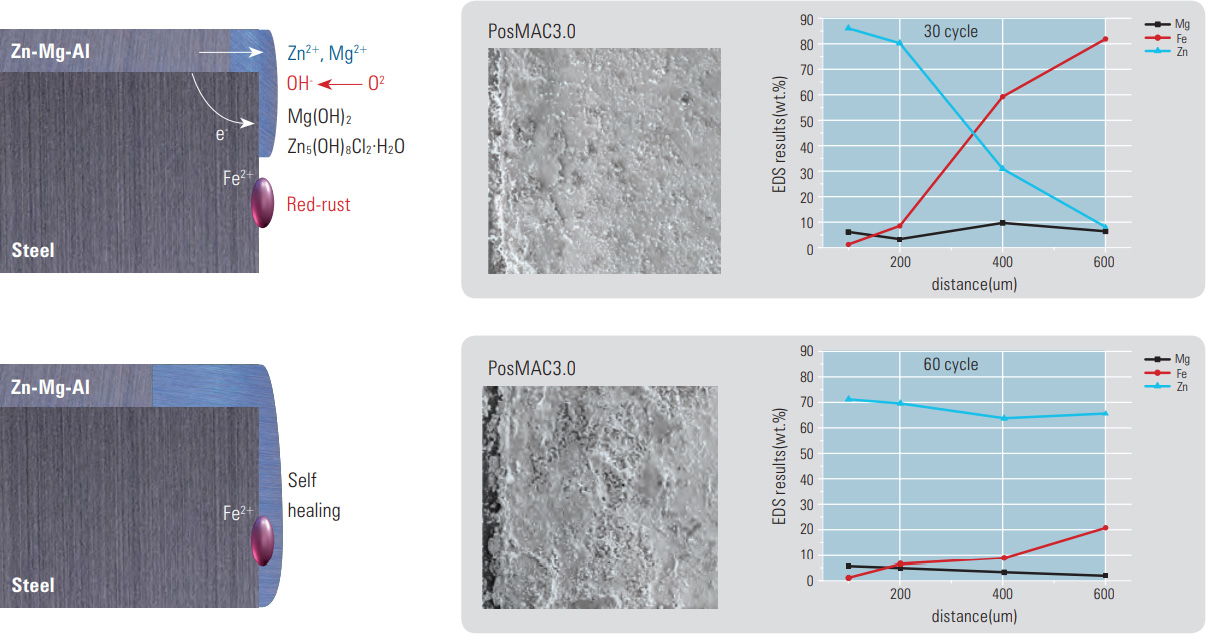

The magnesium(Mg) in PosMAC’s coating layer will accelerate the formation of a dense corrosion product called “Simonkolleite (Zn5(OH)8Cl2·H2O)” which is extremely stable. When simonkolleite is formed on the surface of the coating layer in a film-like-form, it plays a role as a corrosion inhibitor for the base metal.

-

CCT Surface Cross-section 30 cycle

60 cycle

In addition, the upper coating layer can be dissolved to cover the cross-section and accelerate the growth of a stable corrosion product. However red-rust can be found in the already exposed steel plate, but fortunately, the film of the corrosion products covers the cross-section and serves to prevent corrosion

Home

Home